Glossary of Terms

Base: The lower portion of the box that normally holds the item.

Blank: The unfinished chipboard of a box.

2 piece Box: A completed base and lid.

3 Piece Box: A Base and a Lid that includes a NeckTray.

Bookbox: A completed rigid package that includes a Tray and a Bookcover.

Bookcover: A flat piece that is used to make a ‘book-like’ box.

Caliper: Refers to the thickness of the chipboard used.

Deboss: A process where your logo or design is slightly pressed into the paper.

Die Cutting: The cutting of the shape of your box out of a larger piece of chipboard. Boxes are formed using die cutting instead of scoring normally on larger runs.

Emboss: A process similar to debossing, where your logo or design is slightly raised on the paper.

Foam: An insert that is placed into a package to hold contents. Foam can be die cut or used a flat pad.

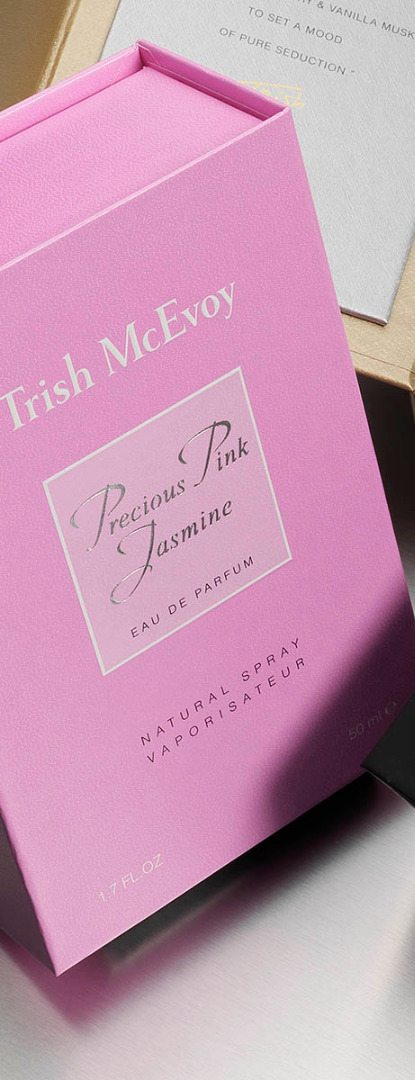

Foil Stamping: Making an impression of a design or logo using foil and a hot stamp.

Lid: The top portion of the box that fits over the base of the box.

Neck: A piece of chipboard that is normally inserted into the base or lid of the box to provide more room for the item to be inserted into the package.

Nest: When a smaller box is placed inside a larger box (usually to save freight costs and space).

Palletize: Placing cartons of packages on a wood pallet (standard is 40" x 48" and about 72" high).

Platform: A folded piece of chipboard that is normally placed in the base of the box to support a product.

Scoring: The process of using a series of knives to cut or create grooves in the chipboard so that it may bend to form a box. Rigid Packages are cut using scoring instead of die cutting on small quantites.

Slipcase: A rigid package used to house books and other media items.

Telescope: Telescoping determines how high the lid will be in relation to the base (usually half or full).

Thumbhole: A cut made in the sides of the base or lid to facilitate its removal from the base of the box.

Turn-in: The portion of the paper which wraps on the inside of the box. Normally extends about 5/8" down each side of the base/lid. If you package requires it, you can request a different turn-in then what is standard.

Vac form insert: A plastic insert (sometimes with a flock surface) used to hold the product in the base of the package.